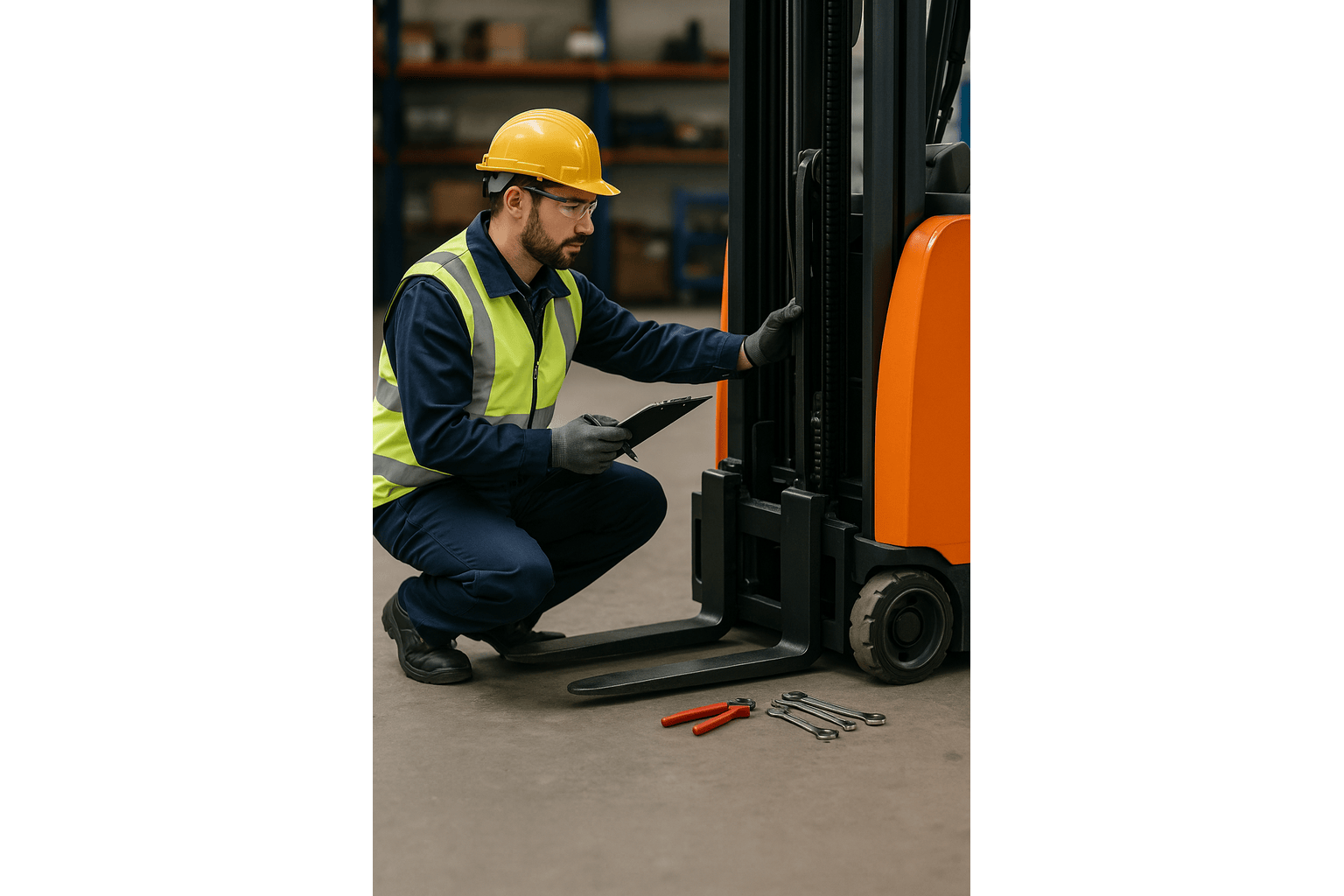

If you depend on forklifts or reach trucks in your operations, the last thing you want is a sudden breakdown. A forklift that won’t start or a reach truck stuck mid-rack can grind work to a halt (and lead to pricey fork truck repair bills). The good news: most forklift problems can be headed off with regular preventive maintenance. We’ve put together a practical checklist to help you keep your forklifts and reach trucks in top shape. By following these tips, you’ll improve safety, reduce downtime, and extend the life of your equipment.

Whether you have an electric reach truck zipping through narrow aisles or a gas-powered fork truck hauling outdoors, a consistent maintenance routine is key. Let’s dive into the checklist – from daily checks to periodic servicing – and when to call in a professional forklift service.

Daily Pre-Shift Inspection (Your First Line of Defense)

Operators should perform a quick check every day before using the forklift (or each shift if multiple shifts). This isn’t just a good idea – OSHA requires daily pre-operation inspections for powered industrial trucks. It only takes a few minutes and can catch small issues before they become big ones. Here’s your daily forklift checklist:

-

Visual Walkaround: Do a 360° walk around the forklift or reach truck. Look for obvious damage or leaks (e.g., puddles of oil, hydraulic fluid, or coolant on the floor). Check that no parts are loose or hanging.

-

Forks & Mast: Inspect the forks for cracks, bends, or excessive wear. Confirm the fork pins are secure. Look at the mast chains for proper tension and lubrication. Any damaged chain links or leaky mast cylinders? If so, tag it out for repair.

-

Tires: Ensure tires are in good shape. For pneumatic tires, check pressure and look for cuts or bulges. For solid tires, look for chunking or excessive wear. Bad tires affect stability – don’t ignore them.

-

Fluid Levels: Check fuel level (propane, diesel, etc.) or battery charge on electric units. Also glance at engine oil, hydraulic fluid, and coolant levels if applicable. Low levels could indicate a leak or just mean it’s time to top off.

-

Safety Devices: Test the brakes (do they feel and sound normal?). Set and release the parking brake to ensure it holds. Verify all lights work (headlights, tail/brake lights, warning beacon). Honk the horn. If there’s a backup alarm or blue spot light, make sure those function. And always confirm the seat belt is present and in good condition.

-

Steering & Hydraulics: Start the forklift and listen. Turn the steering wheel full left and right – it should respond smoothly. Operate the mast controls (lift, tilt, reach if it’s a reach truck) without a load – movements should be smooth and no unusual noises (no grinding, squealing, etc.).

-

Cleanliness: Remove any debris from the operator area. Trash or shrink-wrap under pedals can interfere with operation. Also ensure the floor is clear of oil or grease that could cause slips.

If the daily check finds a serious issue – like faulty brakes or a leaking hose – do not use the forklift. Lock it out and report it so repairs can be made. A short downtime for maintenance beats a major accident or breakdown later.

Regular Maintenance Tasks (Weekly or Monthly)

Besides daily inspections, schedule routine maintenance for your forklifts. The exact interval can depend on usage hours, so refer to your manual, but here are common tasks:

-

Lubrication: Grease the mast slides/channels, pivot points, and lift chain if applicable. A well-lubricated mast and linkage reduce wear and strain on the forklift. Also, keep joints and fittings (like kingpins on the steer axle) greased per the manufacturer’s schedule.

-

Battery Care (Electric Forklifts): For lead-acid batteries, check water levels in each cell after charging (water expands when charged). Top up with distilled water to cover the plates if low. Inspect battery terminals and cables for corrosion – clean them if needed (using proper safety gear). Also, keep the battery tops clean and dry; dirt can cause discharge.

-

Engine & Fuel System (IC Forklifts): For propane, diesel, or gasoline forklifts, perform regular engine check-ups. Weekly or so, check engine oil and coolant levels more thoroughly (beyond the daily quick check). Inspect the air filter – a clogged filter can reduce performance or cause engine issues; clean or replace it as needed. Check the propane tank condition and hose connections (for cracks or leaks – use a bit of soapy water on connections to detect bubbling from leaks). For diesel, drain the fuel water separator if your machine has one.

-

Hydraulic System: Look over hydraulic hoses and fittings for wear or rubbing spots. A hose that’s chafing against the mast or frame can eventually fail. Wipe down accessible hoses and cylinders and then operate the forklift – fresh leaks will be easier to spot on a clean surface.

-

Brakes & Wheels: At least monthly, inspect brake performance. In a quiet area, do a brake test – the forklift should stop firmly without pulling to one side. Check parking brake holds on a slight incline. If you can, peek at brake linings through the wheel (some forklifts have inspection holes) – ensure they’re not worn dangerously thin. Also, check wheel nuts are tight and hub oils (if wet-brake axles) are at proper level.

-

Clean Radiator & Filters: For engine forklifts, blow out or vacuum the radiator and cooling slots to remove dust and debris. An overheated engine or transmission can shorten life drastically. Similarly, check any hydraulic oil cooler or vent screens. For electric units, ensure the motor vents are clear of dust (electric motors need cooling too).

-

General Inspection: Tighten any loose bolts, nuts, or screws you spot. Check that decals and safety labels (like load capacity charts) are still legible. Little things like a missing bolt in an overhead guard or a broken gauge can be caught and fixed during these routine checks.

Keep a log of these maintenance items. Many companies use a simple checklist that the maintenance person or operator signs off weekly or monthly. This not only ensures it gets done, but also creates a record if you ever need to show OSHA or management the upkeep being performed.

Scheduled Professional Service (Quarterly or Annually)

Even with diligent in-house maintenance, it’s smart to have a professional technician service your forklifts on a regular schedule – often every 200 hours of operation or quarterly, whichever comes first (for heavy use), or maybe semi-annually to annually for lower use machines. Here’s what professional forklift service usually includes:

-

Deeper Inspection: A certified tech will inspect things in detail – from mast roller wear to the thickness of brake shoes to the condition of your lift chains (they can measure stretch). They’ll often plug into the forklift’s computer (for newer models) to check for any error codes or performance issues that aren’t obvious.

-

Tune-Up & Fluid Changes: Just like a car, forklifts need periodic tune-ups. That can include changing engine oil and filter, replacing fuel filters, changing hydraulic oil and filter, and maybe replacing spark plugs (for gasoline engines) or servicing the cooling system. For electric forklifts, it might involve checking the drive motors, topping up gearbox oil, and testing the battery and charger performance.

-

Adjustments: Over time, things like brakes, inching pedals, and mast chains might need adjusting. Technicians will adjust brake linkages, mast chain tension, steer alignment, etc., to keep the forklift operating safely and smoothly.

-

Replace Wear Parts: A preventive maintenance service is a good time to replace things that wear out before they fail completely. That could be tires (a tech might notice they’re at the wear line), worn hoses, drive belts, or fork tines that have become too thin (forks should be replaced if they’re worn 10% or more from original thickness). It’s better to schedule a replacement than have, say, a fork break during operation.

-

Operational Test: After servicing, the tech will often test drive the forklift, with and without a load if possible, to ensure everything is working well – brakes stopping correctly, no odd noises, smooth lifting, etc.

If you don’t have a service contract, find a reputable local forklift service provider. (Pro tip: when searching, use your location plus keywords like “forklift maintenance” – e.g., forklift maintenance near me – to find nearby technicians. It’s great to have someone local in an emergency.) Regular professional check-ups are like doctor visits for your forklift – they keep minor issues from turning into major failures.

(Many manufacturers have recommended service intervals and checklists – it’s wise to follow those. If you’ve lost the manual, you can often download a PDF from the manufacturer’s website.)

Quick Maintenance Tips and Habits

Beyond formal checklists, instill good daily habits with your team:

-

Clean as You Go: Encourage operators to keep their forklifts clean. A quick wipe-down or sweep-off at the end of a shift can prevent dirt buildup. It’s easier to spot leaks or cracks on a clean machine.

-

Address Minor Issues Early: If an operator reports something like “the steering feels a bit loose” or “the fork slide is sticky,” don’t wait. Investigate and fix it before it leads to a bigger failure. Little fixes (tightening a bolt, adding hydraulic fluid) can prevent big repairs.

-

Keep Spare Parts: It’s wise to keep a few common spare parts on hand, especially if you have multiple forklifts. Things like spark plugs, filters, drive belts, and fuses are inexpensive and can be swapped in quickly if you have them. Downtime while waiting for a $5 part is frustrating – having a small spare parts kit can save the day.

-

Train and Involve Operators: Your forklift operators are the first line of defense. Train them on this maintenance checklist so they understand what to look for. Create a culture where they take pride in “their” machine’s condition. Often operators will notice subtle changes (a new noise, a slight leak) before anyone else – and that early notice is gold for maintenance.

By following this preventive maintenance checklist and staying proactive, you can avoid most common forklift repair emergencies. Well-maintained forklifts not only run longer and cheaper, but they also operate safer – protecting your operators and your products.